- Premium solutions & products

- Global presence with local support

- Quotation within 24 hours

+61 447 734 654

- Request a quote

- Become a customer

+61 447 734 654

The challenge of distilling large volumes of dried Cannabis flower into smaller consumer size packages is not always the first thing that comes to mind when setting up a Cannabis brand.

The post-harvest function of a business can often slip into the shadows behind the allure of pristine flowers and glitzy retail packaging... or crisp clean GMP grade medicine for that matter.

When you begin to break down the process and apply real world scenarios to packaging Cannabis into consumer batches, the numbers add up quickly and the immense task becomes brutally apparent.

Automation is required

An exercise all readers of this article can undertake is to take a bud (or anything close at hand as an example) and weigh it into a set weight. Grab a jar, drop it in. Manually apply a safety seal, screw on the lid and apply a label (that’s straight).

Now imagine repeating this process 10,000 times and assess how long that would have taken...

It quickly becomes apparent that automation is required for most Cannabis businesses to remain viable when distilling cannabis into consumer size packages.

The Cannabis flower is a high value, fragile and lite commodity

When assessing the viability of certain equipment for Cannabis packaging it’s important to remember that Cannabis flower is a very high value, fragile and lite commodity. Any equipment used to speed up the process of packaging should tick three main boxes,

• Be gentle on the flower – Vibration, tearing and squashing of dried Cannabis flower all leads to diminished consumer experience that ultimately effects your brand.

• Be highly accurate – Over packing of even .1 of a gram that multiplies over large harvests quickly adds up to thousands of dollars in lost revenue

• Be reliable and consistent – Downtime and in-ability to meet supply commitments can quickly affect customer relations and have massive implications.

For the above reasons it's extremely important to ensure any automation you introduce is well researched and fit for purpose.

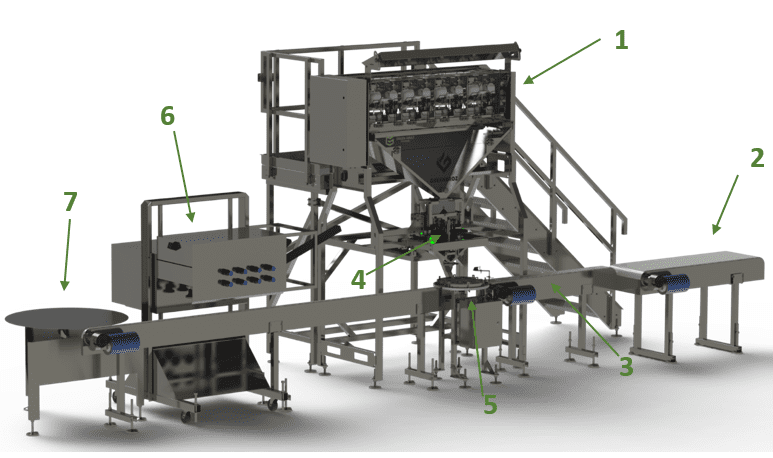

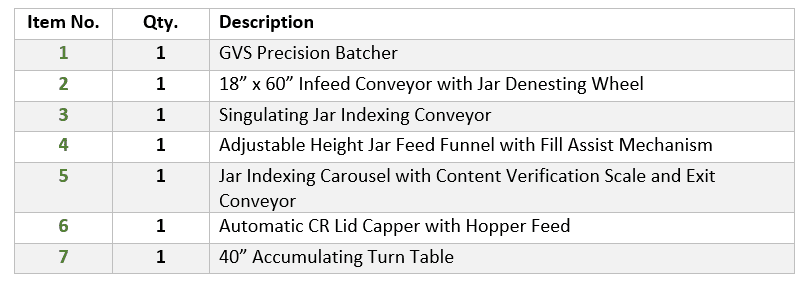

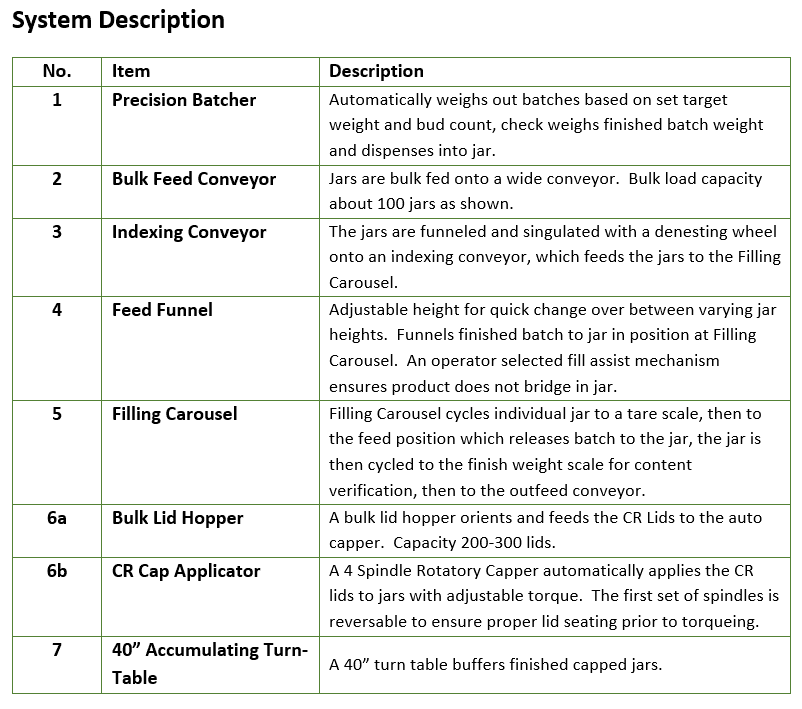

A well sorted production line consisting of Jar sorting, automated weighing and packing, seal application, lid application and labelling can set your business up for years of success regardless of the space you operate in.

The food and beverage industry have relied on the principle of automation for success for decades, and it’s only natural that Cannabis follows suit. When you consider the return-on-investment accurate packaging delivers alone…… it’s a no-brainer, but remember not all creatures are created equal so do your research and ensure that your solution is compliant and fit for purpose.

Cutting-edge Cannabis Processing

Green Vault Systems is the preferred supplier of industrial grade processing and weighing equipment for dried flower processing. We offer professionally engineered solutions which reduce labor costs, increase yields, and improve overall product quality.

Precision Batcher - Where Accuracy Meets Volume

The flexibility and accuracy of the Precision Batcher are second to none when it comes to batching and packaging cannabis flower. The process aids in the preservation of trichomes on your flower, leading to a higher end-potency, better market price, and a consumer experience that lives up to your brand’s high standards.